By Admin on Fri 10 February 2017 in Solenoid Valve FAQ's

Selecting the correct material for your solenoid valve diaphragm, (seal), requires an understanding of available materials. Diaphragms are one of the most limiting factors of a solenoid valve. Here we explain about the types of diaphragm available.

- Chemical properties of the media

- Temperature of the media

- Pressure to be used

Nitrile Rubber (NBR / Buna-N)

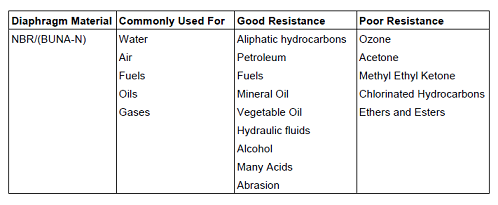

The chemical name for Nitrile rubber is Nitrile Butadiene Rubber. However, most commonly it is referred to as NBR or Buna-N. NBR is probably the most common solenoid valve seal material and it is considered the standard material for neutral fluids by many. NBR is also the standard material for O-rings.

NBR can stand working temperatures from -10 °C up to approximately 90°C on a continuous basis, and higher temperatures intermittently. NBR resists aging caused by heat very well. NBR's resistance to sunlight is very poor however abrasion and tear resistance of NBR is very good.

NBR seals are most commonly used with the following media:

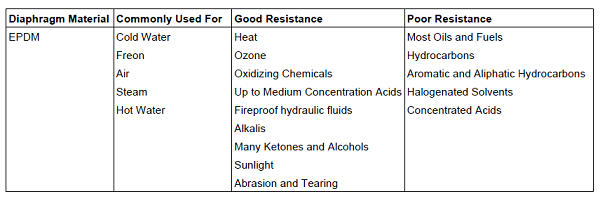

EPDM Rubber

EPDM stands for Ethylene Propylene Diene Monomer rubber. EPDM solenoid valve seals are well suited for use with hot waterand steam due to EPDM's excellent resistance to heat. The working temperatures of EPDM is approximately between -10 °C to +140 °C. EPDM is unsuitable for use with most oils and fuels. WRAS approved EPDM diaphragms are also available.

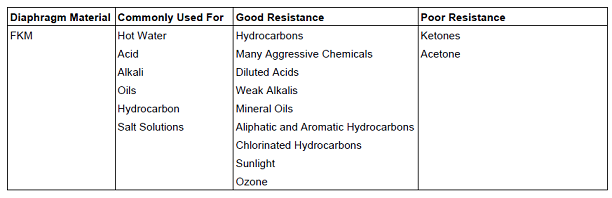

Viton® (FKM)

Viton® (FKM) is a brand name for the Fluoroelastomer manufactured by DuPont. It is well known for its excellent heat resistance, and is suitable for use with oils, combustible gases,fuels, solvents. The working temperatures range from -10°C to + 140 °C.

FKM seals are most commonly used with the following media:

PTFE - Polytetrafluoroethylene

PTFE is a Polytetrafluoroethylene. The most well known trademark of PTFE is DuPont's Teflon. PTFE is practically resistant to all fluids. PTFE is non-elastic, limiting its use in certain applications. PTFE Is particularly good for media reaching very high temperatures often up to 230°C.

Beta Valve Systems Ltd cannot be held responsible for any information provided above. If you need more detailed information on chemical compatibility please contact us or your chemical supplier directly. Click Here for Beta Valve chemical resistance chart.